Streamlining Quality Control: Rotary Joint in Parts Screening with Optical Detection

In the relentless pursuit of manufacturing excellence, where even a single defective part can derail production, parts screening systems are the unsung heroes of quality assurance. At the heart of these setups lies the rotary joint, a pivotal component that enables precise, high-pressure gas delivery for defect rejection. Paired with optical detection technology, the rotary joint facilitates seamless rotational movement, allowing high-pressure air to eject faulty items to designated zones while keeping good parts on track. For North American and European factories aiming for zero-defect lines, this integration promises unparalleled efficiency in parts screening, reducing waste and boosting throughput.

The Role of the Rotary Joint in Optical Detection Systems

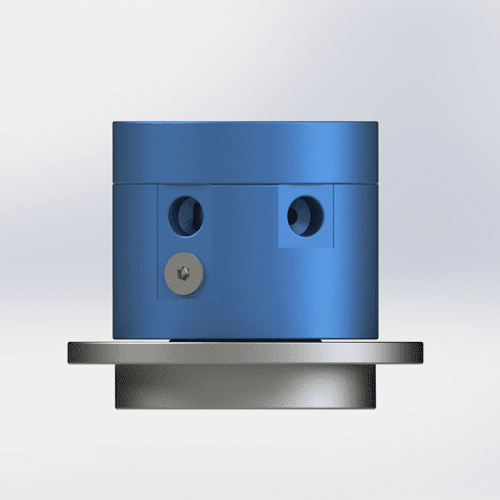

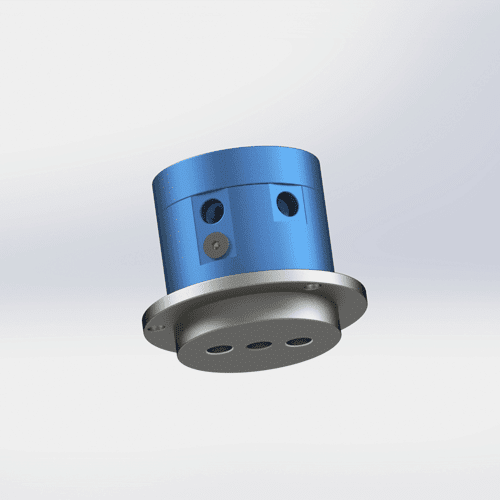

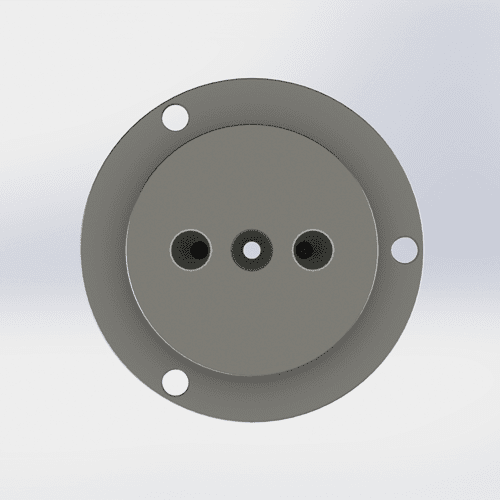

Optical detection uses cameras and sensors to scan components for flaws like scratches or dimensional errors, processing thousands per minute. However, the real magic happens when a rotary joint channels high-pressure gas (up to 30 MPa) through its ports, directing defective parts away from the main flow. In a parts screening application, the rotary joint‘s rotational movement ensures 360° nozzle positioning, blowing rejects with pinpoint accuracy without disrupting the conveyor.

Unlike static systems, the rotary joint in optical detection setups supports multi-axis rotation, maintaining pressure integrity at speeds up to 1000 RPM. Its stainless steel construction and Teflon seals withstand the rigors of continuous operation, making it ideal for parts screening in automotive or electronics assembly.

Case Study: Transforming Electronics Screening at PrecisionFab

PrecisionFab, a Milwaukee-based electronics contract manufacturer, faced escalating defect rates in their parts screening line for circuit board components. Optical detection identified 12% faulty pins, but manual ejection caused 25% cross-contamination, halting lines for 15 minutes hourly and costing $45K monthly in rework.

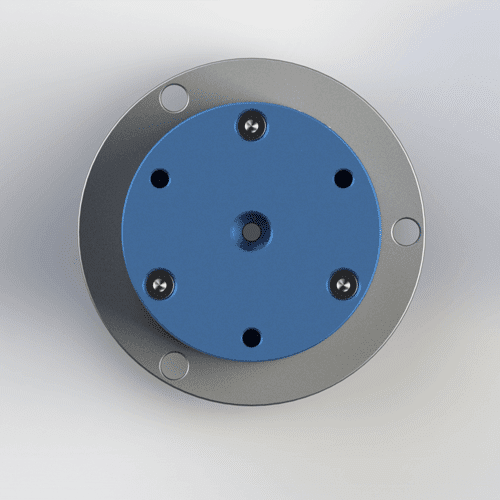

The solution? A custom rotary joint integrated into the optical detection conveyor. Mounted on the rejection station, the rotary joint routed compressed air through dual ports: one for initial blast separation, the other for secondary deflection to a scrap bin 2 meters away. With rotational movement calibrated to 600 RPM, it synchronized with the camera’s 1200 fps scan, ejecting defects mid-conveyor without stopping flow.

Implementation took one week, with minimal downtime. Engineers calibrated the rotary joint using laser alignment for 0.01mm nozzle precision, ensuring high-pressure bursts (20 MPa) targeted only flagged items. Integration with PLC controls added real-time feedback, adjusting air velocity for varying part sizes.

The outcomes were transformative:

Defect Handling: Rejection accuracy soared to 99.5%, slashing cross-contamination to 1%.

Throughput Boost: Line speed increased 40% to 15,000 parts per hour, with zero manual interventions.

Cost Reductions: Monthly rework dropped 85%, saving $38K, while the rotary joint‘s durability cut maintenance by 50%.

ROI: Full payback in six weeks, with scalability for multi-line expansion.

“Adopting the rotary joint for optical detection turned our parts screening from a bottleneck into a powerhouse,” said Quality Lead Sarah Kline. “High-pressure ejection with flawless rotational movement has redefined our zero-defect goal.”

Why Invest in Rotary Joints for Parts Screening?

For manufacturers prioritizing optical precision, the rotary joint offers unmatched integration with optical detection systems. Its ability to manage rotational movement under high-pressure conditions ensures reliable defect isolation, aligning with ISO 9001 standards. In electronics and automotive sectors, this parts screening solution cuts waste by 80%, fostering sustainable operations.

Elevate your quality control—explore how the rotary joint can supercharge your optical detection line. Contact our experts for tailored demos and seamless integration.