Mastering Multi-Channel Automation: The 8 in 8 Out Rotary Joint in Robotic Assembly Lines

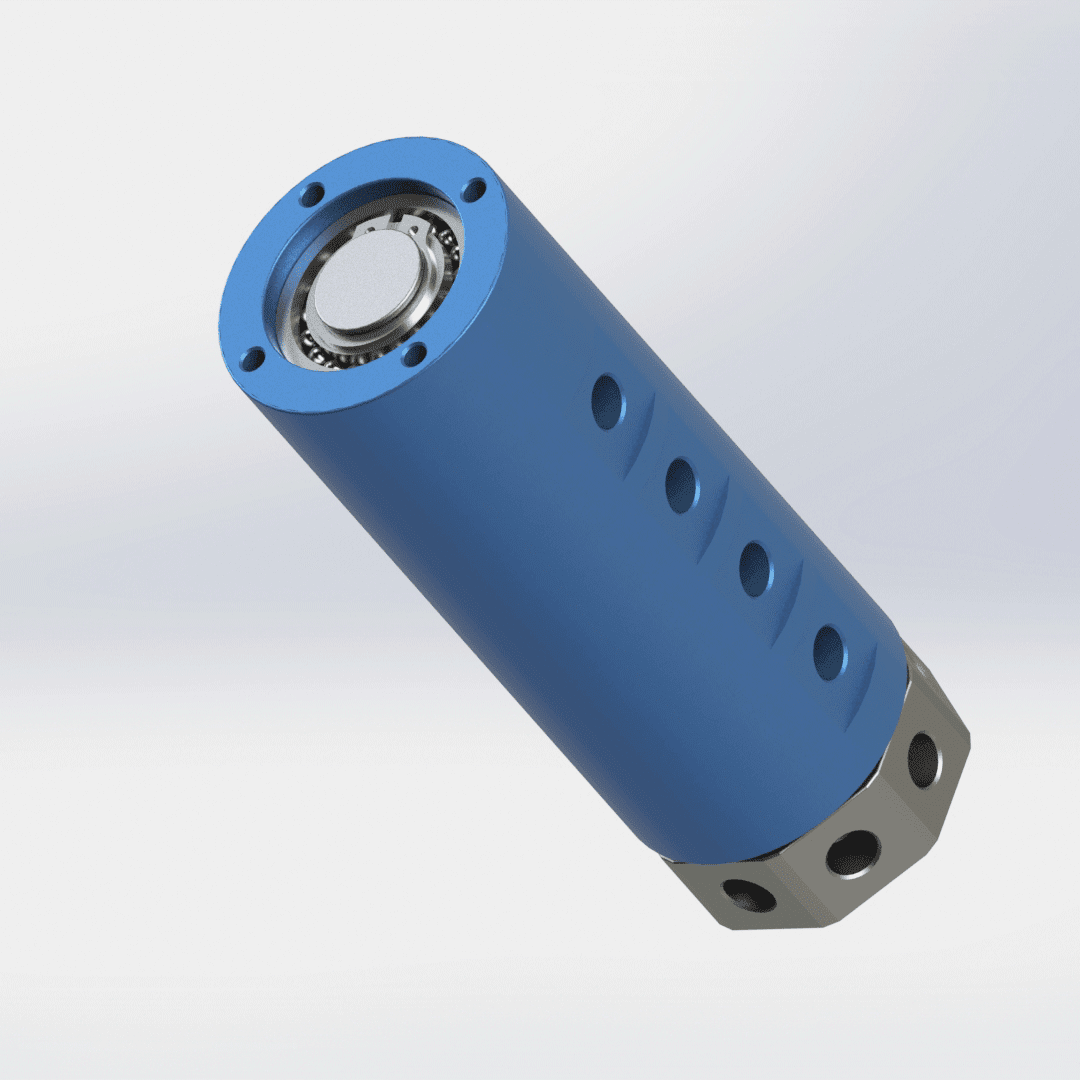

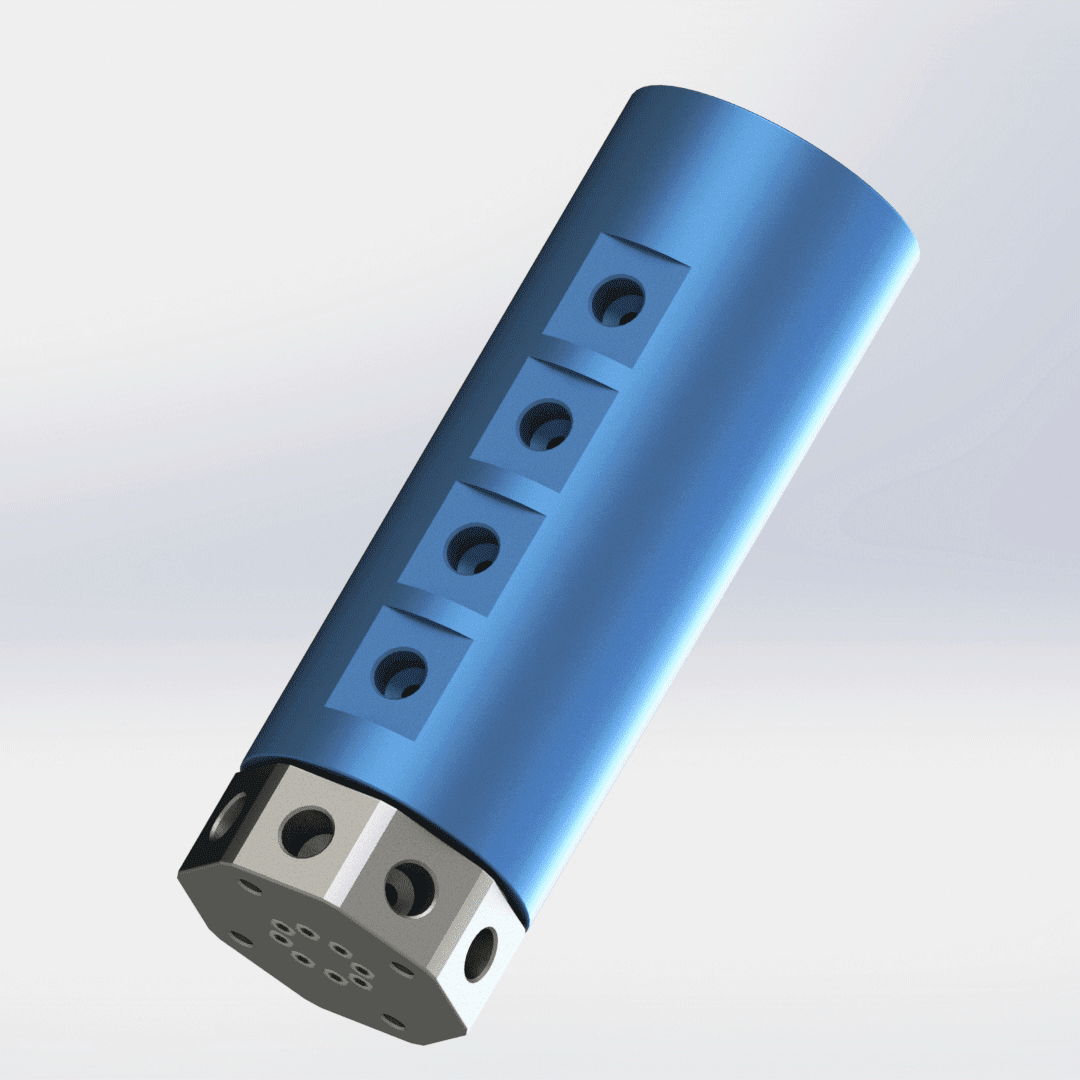

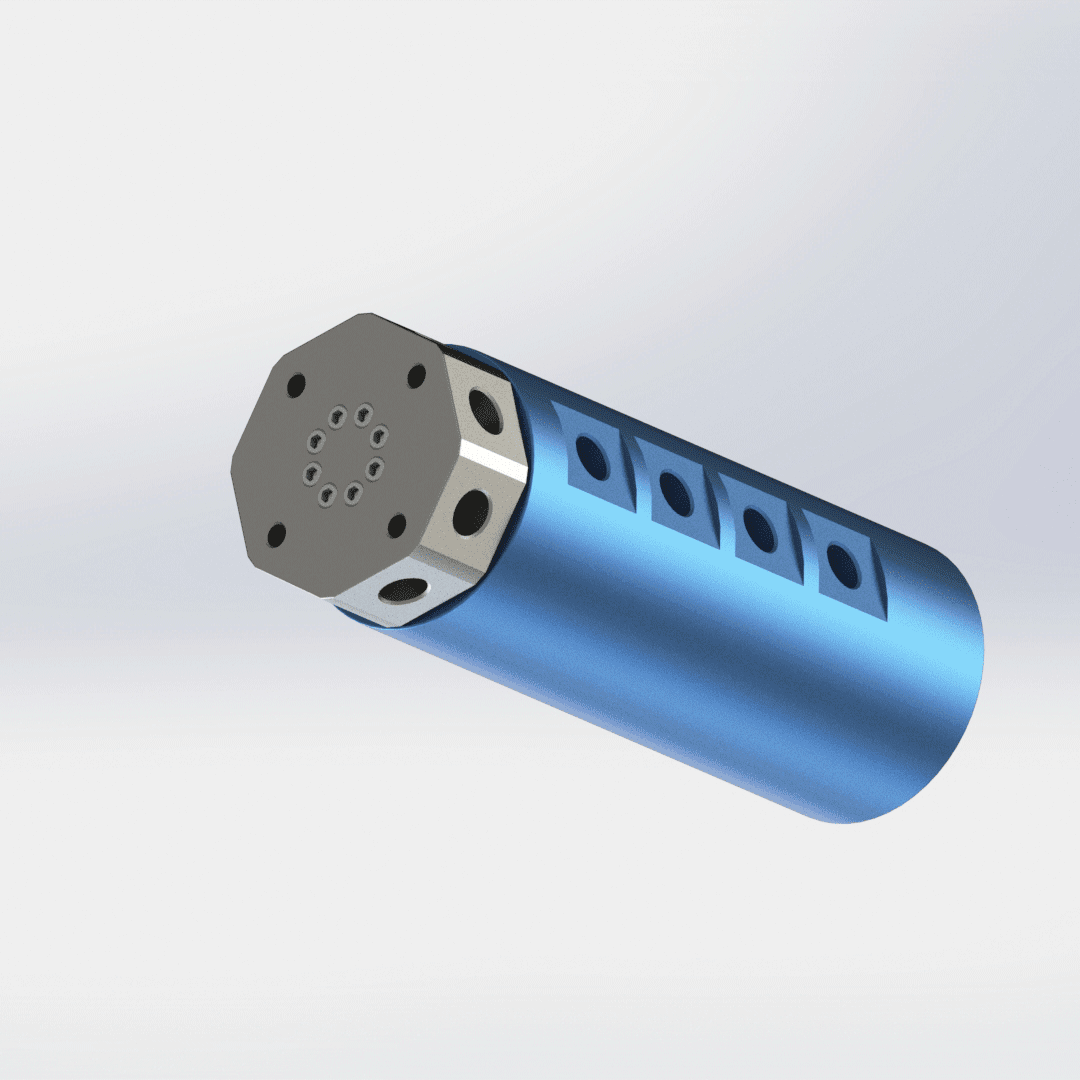

In the intricate dance of industrial robotics, where precision and speed converge, the 8 in 8 out rotary joint serves as the ultimate conduit for complex fluid and signal transmission. This multi-passage rotary joint enables eight simultaneous inlets and eight outlets, facilitating uninterrupted delivery of air, hydraulics, coolants, and electrical signals during 360° rotational movement. Ideal for robotic assembly lines, it minimizes cable tangle and pressure loss, ensuring flawless operation in high-volume environments. For European and North American manufacturers optimizing robotic assembly, the 8 in 8 out rotary joint—crafted from stainless steel with Teflon seals—delivers reliability at pressures up to 40 MPa and speeds exceeding 2000 RPM, revolutionizing workflows from electronics to automotive.

The Technical Prowess of the 8 in 8 Out Rotary Joint

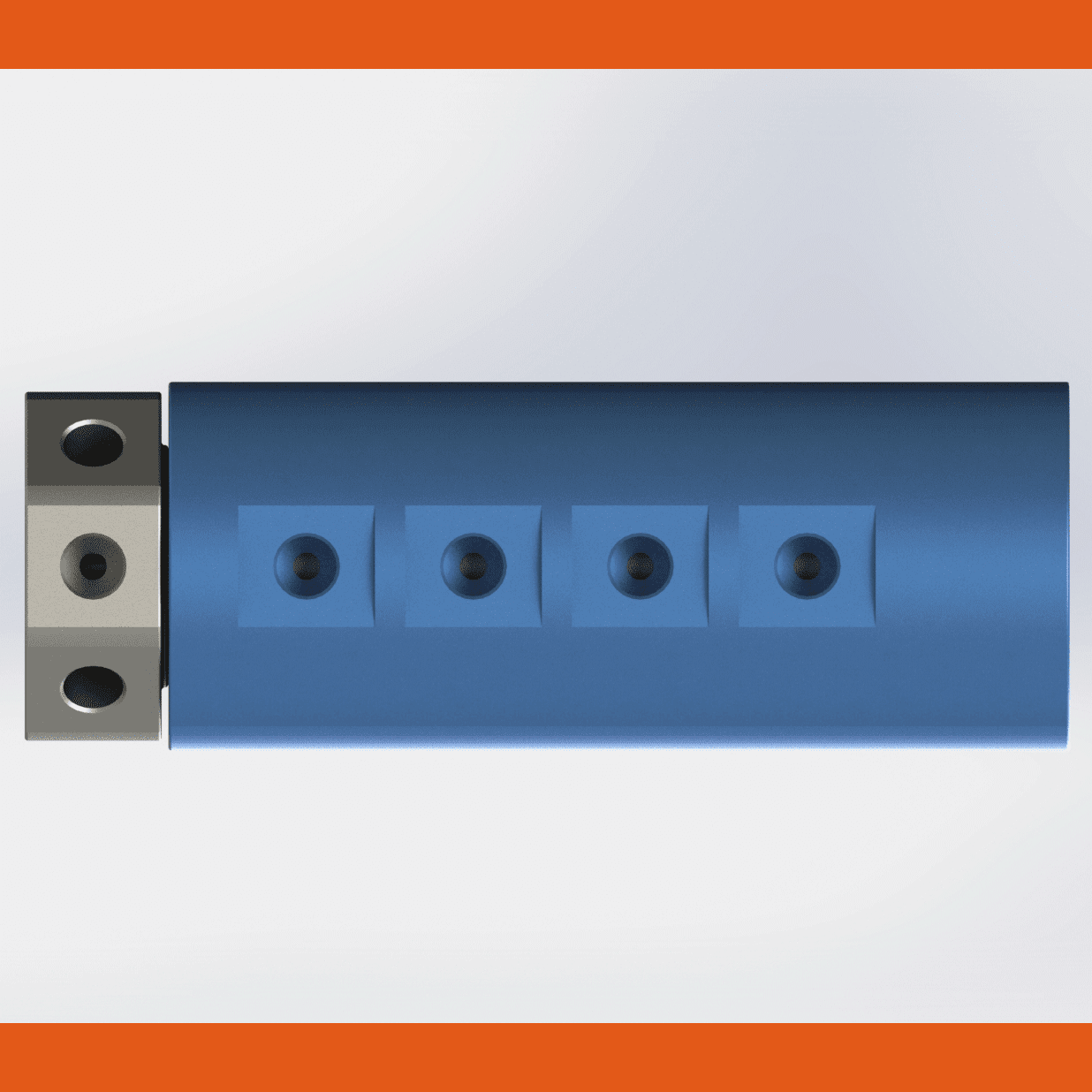

Engineered for versatility, the 8 in 8 out rotary joint features a compact 80mm bore, supporting diverse media like compressed air for pneumatic grippers and hydraulic oil for torque actuators. Its multi-channel rotary joint design incorporates independent seals for each passage, preventing cross-contamination in rotational movement scenarios. Compatible with M10 and NPT 1/2 threads, this rotary joint integrates seamlessly into robotic wrists, enduring temperatures from -10°C to 120°C and vibrations common in robotic assembly lines. Unlike single-channel alternatives, the 8 in 8 out configuration allows parallel operations—simultaneously powering eight solenoid valves for precise part manipulation—cutting cycle times by 45%.

The rotary joint‘s gold-plated contacts ensure signal integrity for Ethernet and sensors, making it indispensable for Industry 4.0 setups where data feedback drives real-time adjustments.

Case Study: Elevating Electronics Assembly at TechForge Robotics

TechForge Robotics, a Boston-based innovator in consumer electronics, confronted bottlenecks in their robotic assembly line for smartphone casings. Legacy rotary joints with limited channels caused hydraulic leaks and signal drops during 360° part flipping, leading to 16% misalignment and 20-minute hourly pauses—equating to $110K in annual losses.

The deployment of the 8 in 8 out rotary joint marked a turning point. Retrofitted into 15 ABB IRB 6700 robots, each rotary joint managed eight channels: four inlets for air/hydraulics to grip and position casings, and four outlets for coolant and vacuum to secure and cool during soldering. The multi-channel rotary joint synced with vision systems, enabling synchronized rotational movement at 1500 RPM without hose stress.

Implementation spanned one week, with PLC reprogramming to calibrate flow rates. Engineers verified the 8 in 8 out rotary joint‘s Teflon seals under 40 MPa bursts, confirming zero leaks across 10,000 cycles.

The results were compelling:

Efficiency Leap: Assembly rates climbed 42% to 2,500 units per shift, with rotational movement precision hitting 99.9%.

Defect Reduction: Misalignment fell 94%, as the rotary joint‘s stable channels eliminated pressure fluctuations.

Cost Control: Downtime halved, saving $85K yearly, while the 8 in 8 out design reduced component count by 25%.

Scalability: Easy M10 threading facilitated expansion to 25 robots without redesign.

“This 8 in 8 out rotary joint is the nerve center of our robotic assembly line,” said Lead Engineer Raj Patel. “Its flawless multi-channel rotary joint performance has redefined our throughput expectations.”

Why This Rotary Joint is Essential for Robotic Assembly

For automation pioneers, the 8 in 8 out rotary joint offers modularity for future-proofing robotic assembly lines and adherence to ISO 10218 safety standards. It cuts energy use by 18% through optimized flow and supports sustainable practices with recyclable materials. In electronics and beyond, where rotational movement demands perfection, this rotary joint is a must-have.

Empower your robots today—discover the 8 in 8 out rotary joint for superior robotic assembly. Contact our specialists for demos and custom configurations.