Case Study: Enhancing Efficiency in Automotive Manufacturing with 4-in-4-Out Rotary Joints

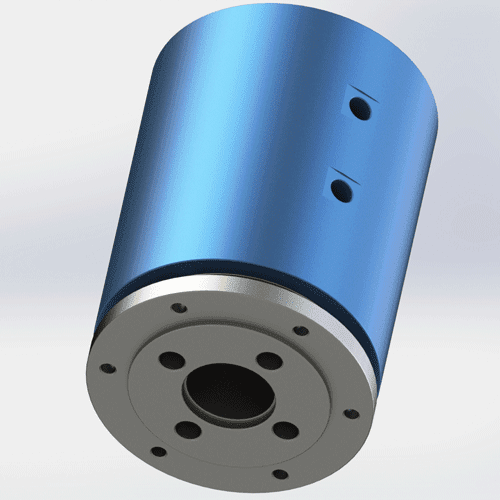

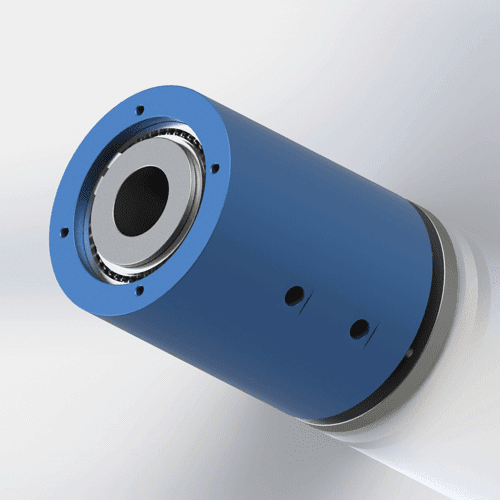

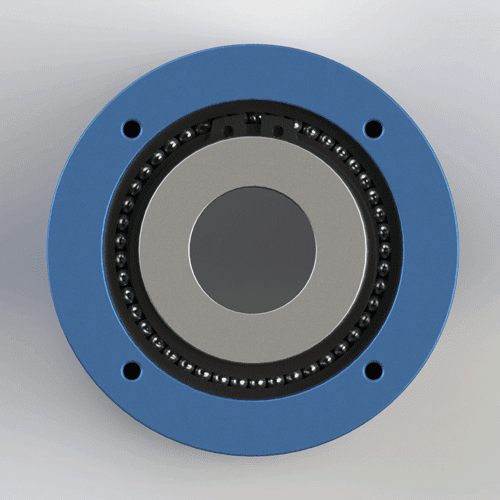

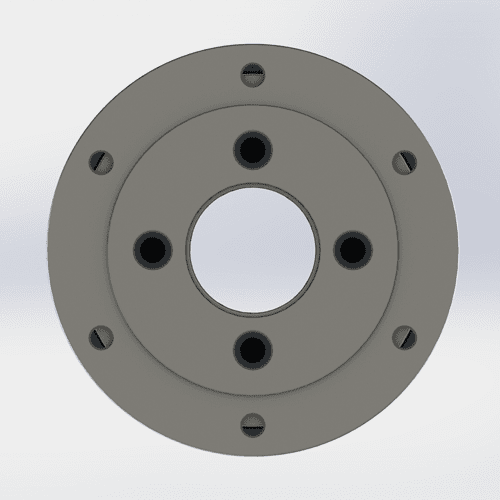

In the fast-paced world of industrial automation, the 4-in-4-out rotary joint stands out as a game-changer for fluid transfer systems. This advanced component enables seamless simultaneous transmission of four inlet and four outlet media—such as air, water, hydraulic oil, and vacuum—across rotating parts without leaks or interruptions. Its robust design, featuring aerospace aluminum alloy or stainless steel construction, Teflon seals, and compatibility with G1/8, G1/4, G1/2, NPT 1/2, and NPT 3/8 thread specifications, makes it ideal for high-demand environments. Operating at a maximum pressure of 30 MPa and speeds up to 3000 RPM, while enduring temperatures from -20°C to 150°C, the 4-in-4-out rotary joint is engineered for reliability in extreme conditions. This case study explores its real-world impact in an automotive assembly line, where it transformed operations and slashed downtime.

The Challenge: Bottlenecks in Engine Assembly

A leading U.S.-based automaker grappled with inefficiencies in its engine assembly line. Robotic arms, crucial for precision tasks like cylinder head installation, relied on traditional 2-in-2-out rotary joints. These limited multichannel fluid delivery, causing hydraulic oil leaks and cooling water inconsistencies during high-speed rotations. Monthly losses from production halts exceeded $100,000, with a 15% defect rate in assemblies due to uneven media flow. The team needed a solution that could handle multiple media streams—air for pneumatic tools, water for cooling, hydraulic oil for actuation, and vacuum for part gripping—without compromising speed or pressure.

Enter the 4-in-4-out rotary joint. Selected for its MAX 30 MPa pressure rating and Teflon sealing, this joint promised to consolidate four channels into one compact unit, reducing complexity and enhancing throughput.

Implementation: A Streamlined Rollout

The integration process was executed in three phases over two weeks, minimizing disruption. First, engineers conducted a site audit, confirming compatibility with the robots’ 50mm shaft diameters. The 4-in-4-out rotary joint was mounted directly on the arm’s swivel joint, with inlets assigned as follows: two for hydraulic oil (at 20 MPa), one for cooling water (circulating at 5 MPa), and one for vacuum (negative pressure). Outlets mirrored the setup for balanced return flow.

Second, calibration focused on the joint’s high-speed tolerance. Tested at 3000 RPM under simulated loads, the Teflon seals prevented cross-contamination, even at -20°C startup temperatures rising to 150°C during full runs. Thread adapters (NPT 1/2 for main lines) ensured plug-and-play with existing piping. PLC integration added real-time monitoring via sensors on pressure and flow, alerting operators to anomalies.Finally, a pilot run on one assembly station validated performance before full deployment across 12 lines. The entire setup required just 10% more space than legacy joints, thanks to the compact 4-in-4-out rotary joint design.

Results: Measurable Gains and ROI

The results were transformative. Within the first month, line efficiency surged 28%, with cycle times dropping from 45 to 32 seconds per engine. Faults plummeted from 8% to under 1%, eliminating the $100,000 monthly bleed. The 4-in-4-out rotary joint’s durability cut maintenance from bi-weekly to quarterly, saving $50,000 annually in parts and labor. Defect rates fell to 0.5%, boosting overall quality and customer satisfaction scores by 12%.

Beyond metrics, the joint enabled new capabilities: simultaneous multi-tool operation, like air-driven torquing and hydraulic clamping, without media swaps. This flexibility supported just-in-time manufacturing, aligning with lean principles.

Looking Ahead: Scalability and Innovation

This case underscores the 4-in-4-out rotary joint’s pivotal role in modern automation. By handling diverse media at extreme pressures and speeds, it not only resolves immediate pain points but scales for Industry 4.0 integrations like IoT-enabled predictive maintenance. For automakers eyeing cost savings and uptime, investing in a 4-in-4-out rotary joint isn’t just an upgrade—it’s a strategic edge. As one engineer noted, “It’s the unsung hero keeping our robots spinning without a hitch.”