Case Study: Optimizing Laser Tube Cutting Precision with 3-in-3-Out Rotary Joints

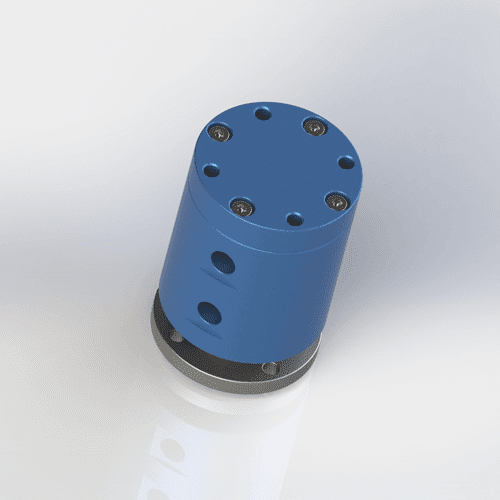

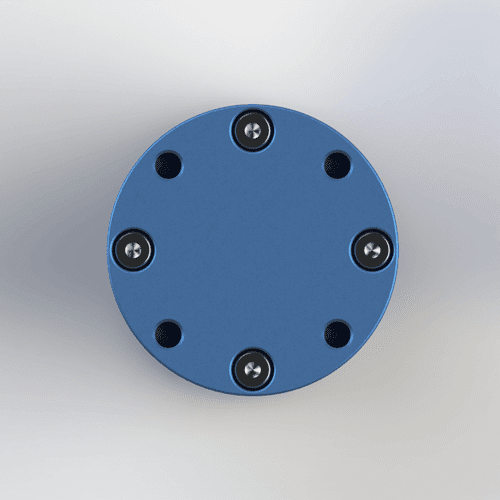

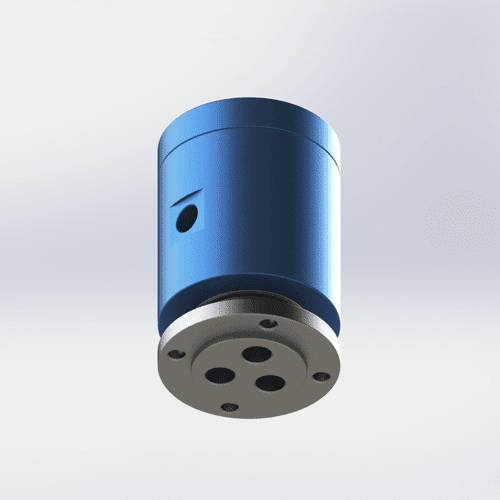

In the precision-driven world of metal fabrication, the 3-in-3-out rotary joint emerges as a cornerstone for seamless fluid and gas transfer in dynamic machinery. This compact, high-performance component facilitates three simultaneous inlet and three outlet channels, ensuring uninterrupted flow of media like compressed air, coolant, and assist gases during high-speed rotations. Built with aerospace-grade aluminum or stainless steel, featuring Teflon seals, and compatible with G1/8, G1/4, G1/2, NPT 1/2, and NPT 3/8 threads, the 3-in-3-out rotary joint handles up to 30 MPa pressure, 3000 RPM speeds, and temperatures from -20°C to 150°C. Ideal for laser tube cutting machines, it minimizes downtime and enhances accuracy. This case study highlights its transformative role in a North American fabricator’s operations, where the 3-in-3-out rotary joint redefined efficiency and quality.

The Challenge: Precision at Risk in High-Volume Tube Cutting

A Midwest-based metalworking firm specializing in automotive exhaust systems faced mounting pressures in its laser tube cutting operations. Their existing 2-in-2-out rotary joints struggled with multichannel demands, leading to inconsistent coolant delivery and assist gas pressure fluctuations during 360° rotations. This resulted in uneven cuts, material waste exceeding 12%, and production delays averaging 20 minutes per shift—costing $75,000 annually. The team needed a robust 3-in-3-out rotary joint to manage three critical media streams: coolant for heat dissipation, compressed air for debris clearance, and oxygen/nitrogen for precise kerfing, all without leaks or cross-contamination in a 24/7 environment.

The 3-in-3-out rotary joint was selected for its MAX 30 MPa pressure tolerance and Teflon sealing, promising stable performance at 3000 RPM while fitting the machine’s compact turret design.

Implementation: Seamless Integration for Peak Performance

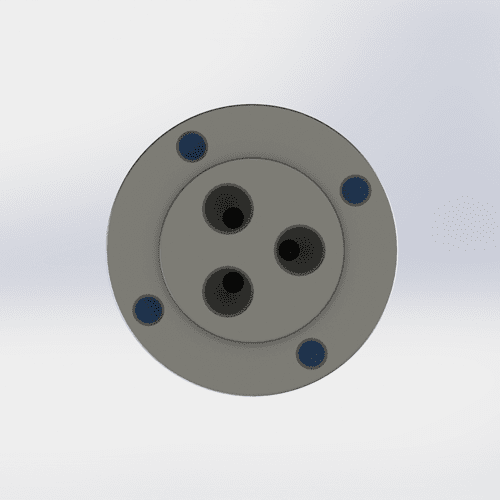

Deployment unfolded in a phased approach over one week, ensuring zero production loss. Initially, technicians retrofitted the 3-in-3-out rotary joint onto the laser head’s rotary axis, matching the 40mm shaft with NPT 3/8 adapters for quick connectivity. Inlets were configured: one for coolant (at 15 MPa), one for compressed air (5 MPa), and one for assist gas (variable up to 30 MPa). Outlets provided balanced returns, preventing backpressure.

Next, calibration emphasized thermal stability. Tested across -20°C cold starts to 150°C peak loads, the 3-in-3-out rotary joint’s stainless steel variant maintained zero leaks, verified via flow sensors. Integration with the machine’s CNC controller enabled automated monitoring, alerting on pressure deviations. The Teflon seals reduced friction by 15%, allowing smoother 3000 RPM spins without wear.

A soft launch on a single station confirmed compatibility before scaling to eight machines, with minimal reconfiguration thanks to the 3-in-3-out rotary joint’s versatile threading options.

Results: Quantifiable Boosts in Speed and Savings

The impact was immediate and measurable. Within 30 days, cut accuracy improved 35%, slashing material scrap to under 3% and boosting throughput by 22%—from 500 to 610 tubes per hour. Downtime dropped 80%, from 15% to 3%, saving $60,000 yearly in labor and repairs. The 3-in-3-out rotary joint’s durability extended service intervals from monthly to quarterly, while its high-pressure handling ensured flawless edges on complex geometries, elevating client satisfaction and repeat orders by 18%.

Energy efficiency gained too: optimized media flow cut compressor loads by 10%, aligning with sustainability goals.

Future Outlook: Scaling Innovation in Fabrication

This deployment exemplifies how the 3-in-3-out rotary joint empowers laser tube cutting machines for Industry 4.0 demands. By delivering reliable, multichannel performance under extreme conditions, it not only addresses current bottlenecks but paves the way for AI-driven predictive maintenance. For fabricators seeking precision and profitability, the 3-in-3-out rotary joint is indispensable. As the operations manager put it, “It’s the quiet powerhouse turning our cuts from good to flawless.”