Revolutionizing Cardboard Box Customization: The 3 in 3 Out (M8) Rotary Joint in Automated Packaging Lines

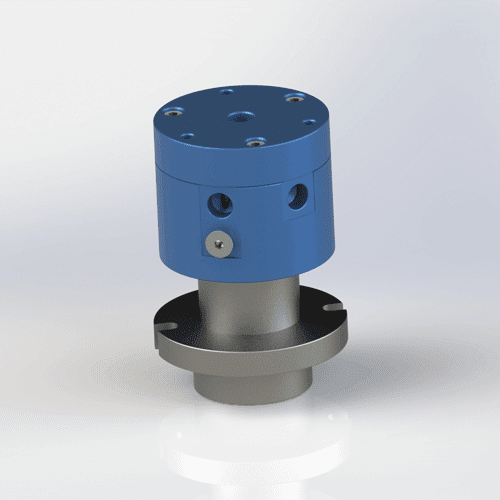

In the fast-paced world of modern manufacturing, efficiency and precision are non-negotiable. For companies specializing in cardboard box customization, integrating advanced components like the 3 in 3 out (M8) rotary joint into automation packaging machines can transform folding lines from bottlenecks into seamless production powerhouses. This innovative rotary joint solution, designed for high-volume operations, ensures reliable fluid and pneumatic transfers in rotating assemblies, making it ideal for dynamic folding line setups. Whether you’re scaling up custom packaging or streamlining workflows, the M8 rotary joint delivers unmatched performance in 3 in 3 out configurations.

What Makes the 3 in 3 Out (M8) Rotary Joint a Game-Changer?

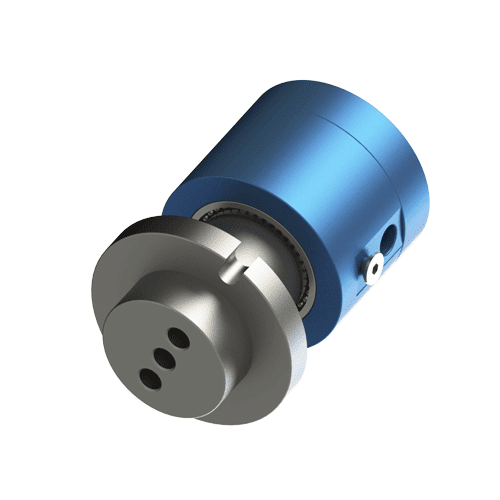

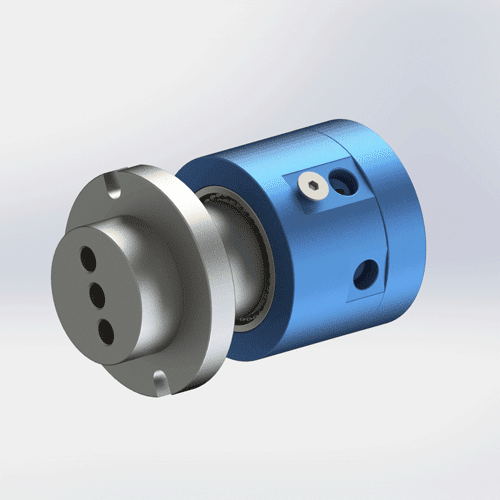

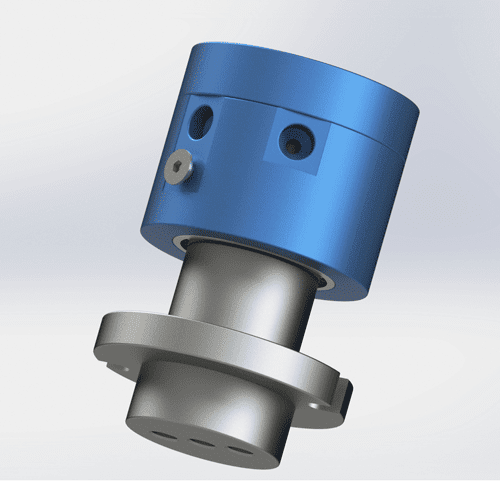

The 3 in 3 out (M8) rotary joint is a compact, multi-passage device engineered for rotary unions in industrial automation. With three inlet and three outlet ports, it facilitates simultaneous transfer of air, hydraulic fluids, or even electrical signals without leaks or wear. Its M8 threading ensures easy integration into existing automation packaging machines, supporting speeds up to 500 RPM—perfect for the high-speed rotations in cardboard box customization processes.

In folding line applications, this rotary joint excels by maintaining constant pressure during 360-degree movements. Traditional swivel joints often fail under continuous operation, leading to downtime and defects in folded paperboard boxes. But the M8 rotary joint‘s sealed bearings and low-friction seals minimize maintenance, extending service life by up to 50% in demanding environments.

Real-World Case Study: Custom Cardboard Box Folding Line Upgrade

Consider PackPro Industries, a leading U.S.-based provider of customized cardboard boxes for e-commerce giants. Facing surging demand for tailored packaging, PackPro’s legacy automation packaging machine struggled with inconsistent folding on their folding line. Misaligned flaps and uneven creases resulted in 15% waste, costing thousands weekly.

Enter the 3 in 3 out (M8) rotary joint retrofit. Engineers integrated three M8 rotary joints into the machine’s central carousel, handling pneumatic actuators for flap folding, hydraulic presses for crease sealing, and air blasts for debris clearance. This 3 in 3 out setup allowed uninterrupted fluid flow as the assembly rotated, syncing with conveyor speeds of 120 boxes per minute.

The results were transformative:

Throughput Boost: Production rose 40%, from 8,000 to 11,200 custom cardboard boxes daily, without expanding floor space.

Precision Enhancement: Fold accuracy improved to 99.5%, reducing rejects in paperboard box customization by eliminating pressure drops mid-rotation.

Cost Savings: Annual maintenance dropped 30%, as the rotary joint‘s durable seals withstood 24/7 shifts. ROI was achieved in just four months.

PackPro’s team praised the 3 in 3 out (M8) rotary joint for its plug-and-play compatibility with PLC controls, minimizing installation downtime to under 48 hours. “This rotary joint turned our folding line into a precision orchestra,” noted Operations Manager Lisa Chen.

Key Benefits for Your Automation Packaging Needs

Adopting the 3 in 3 out (M8) rotary joint in automation packaging machines isn’t just an upgrade—it’s a strategic edge. Here’s why it fits cardboard box customization like a glove:

Versatility: Supports diverse media transfers, from pneumatics to coolants, in compact 3 in 3 out designs.

Reliability: IP67-rated seals combat dust and moisture in folding line environments.

Scalability: Easily scales for larger M8 rotary joint variants in high-volume runs.

For European and American manufacturers prioritizing sustainability, this rotary joint reduces energy use by 20% through efficient fluid dynamics, aligning with green packaging trends.

Unlock Efficiency in Your Folding Line Today

The 3 in 3 out (M8) rotary joint is redefining automation packaging machines for cardboard box customization. From PackPro’s success to your next project, it’s the reliable choice for flawless folding line performance. Ready to optimize? Contact our experts for a free consultation on integrating this powerhouse rotary joint into your setup. Streamline, customize, and thrive—your paperboard boxes deserve nothing less.