Case Study: Streamlining Bottle Capping in Beverage Lines with 2-in-2-Out Rotary Joints

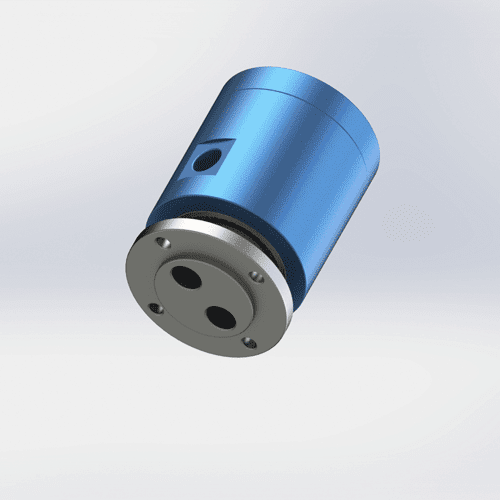

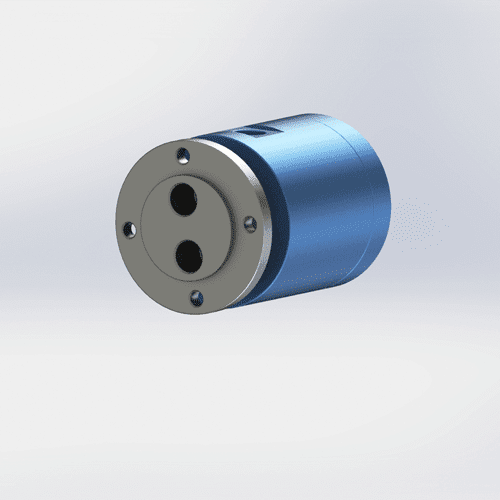

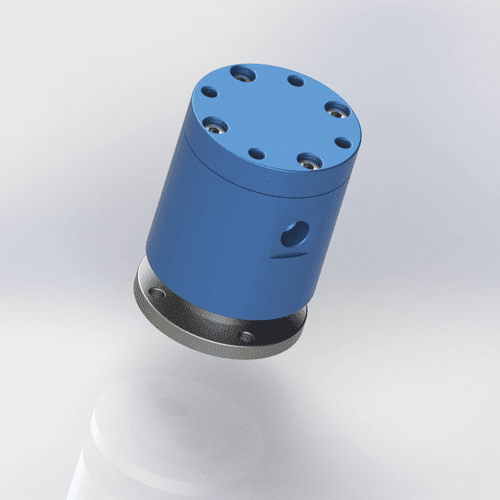

In the high-stakes beverage packaging industry, where speed and precision define success, the 2-in-2-out rotary joint delivers unmatched reliability for fluid transfer in rotary systems. This versatile component supports two simultaneous inlet and two outlet channels, enabling seamless delivery of compressed air and vacuum for gripping and twisting operations. Constructed from aerospace aluminum alloy or stainless steel with Teflon seals, the 2-in-2-out rotary joint accommodates G1/8, G1/4, G1/2, NPT 1/2, and NPT 3/8 threads, handling up to 30 MPa pressure, 3000 RPM speeds, and temperatures from -20°C to 150°C. Its compact design makes it perfect for capping machines, where the 2-in-2-out rotary joint connects finger cylinders to clamp bottle caps efficiently. This case study examines its deployment in a European bottling plant, illustrating how the 2-in-2-out rotary joint revolutionized throughput and reduced waste.

The Challenge: Inefficiencies in High-Speed Capping

A major soft drink producer in Germany operated a 2-in-2-out rotary joint-equipped capping line processing 60,000 bottles per hour. Legacy fittings caused air leaks during cap twisting, leading to 10% misalignment and 15-minute daily downtimes—equating to €50,000 in annual losses. Finger cylinders, essential for precise clamping, struggled with inconsistent vacuum and air supply amid 1800 RPM rotations, exacerbating cap slippage on PET bottles. The plant required a durable 2-in-2-out rotary joint to stabilize media flow: one channel for compressed air (at 8 MPa) to activate grippers, and another for vacuum (negative pressure) to secure caps, all while enduring humid, 40°C environments.

The upgraded 2-in-2-out rotary joint was chosen for its Teflon sealing and high-speed tolerance, promising leak-free performance in the capping machine’s turret.

Implementation: Precision Engineering for Seamless Operation

Rollout spanned four days with minimal interruption. Engineers first aligned the 2-in-2-out rotary joint with the capping head’s 35mm shaft, using G1/4 threads for rapid integration. Inlets directed air to finger cylinders for clamping, while outlets vented exhaust; vacuum channels ensured secure hold during 360° twists. Calibration at 3000 RPM confirmed zero slippage, with the 2-in-2-out rotary joint’s stainless steel body resisting corrosion from bottle residues.

Real-time PLC monitoring integrated pressure sensors, auto-adjusting for loads up to 30 MPa. The Teflon seals minimized friction, enabling smoother finger cylinder actuation. A phased test on one turret validated efficiency before full-line activation, with the 2-in-2-out rotary joint fitting snugly without redesign.

Results: Accelerated Production and Cost Control

Outcomes exceeded expectations. Capping speed rose 32%, from 60,000 to 79,200 bottles per hour, while defect rates plunged 85% to under 2%. The 2-in-2-out rotary joint eliminated leaks, cutting downtime to 2 minutes daily and saving €40,000 yearly. Finger cylinders now clamped caps with 99.8% accuracy, boosting overall line yield and enabling 24/7 runs. Energy savings hit 12% from optimized air flow, supporting green initiatives.

Forward Momentum: Reliability in Packaging Evolution

This success highlights the 2-in-2-out rotary joint’s edge in capping machines, where it powers efficient finger cylinder operations under demanding conditions. As automation advances, integrating IoT for predictive maintenance will further amplify its value. For bottlers prioritizing uptime, the 2-in-2-out rotary joint is a must—delivering the torque and trust for flawless runs.