Precision Clamping in Action: Rotary Joint Powers 4-Station Rotary Indexing Table for Automated Machining

In the competitive landscape of precision manufacturing, where every second counts, the 4-station rotary indexing table stands as a cornerstone of efficiency. This automated system cycles workpieces through multiple operations—clamping, drilling, threading, chamfering, and assembly—while the rotary joint ensures reliable pneumatic clamping force for the fixture’s pneumatic cylinder. By delivering uninterrupted air supply during 360° rotational movement, the rotary joint enables seamless transitions between stations, minimizing downtime in high-volume production. For automotive and aerospace fabricators in North America and Europe, integrating a rotary joint into 4-station rotary indexing tables transforms machining from manual drudgery to automated excellence.

The Challenge: Achieving Consistent Clamping in Multi-Station Machining

A leading Ohio-based automotive supplier grappled with inconsistent clamping in their 4-station rotary indexing table. The pneumatic cylinder in the fixture struggled to maintain 500 N clamping force across rotations, leading to workpiece slippage during drilling and threading. First station drilling holes often misaligned, second-station threading produced burrs, third-station chamfering left rough edges, and fourth-station assembly required manual intervention—resulting in 22% defect rates and 30-minute daily halts, costing $60K annually.

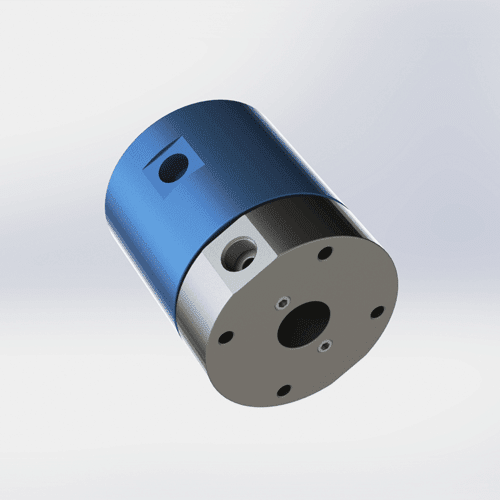

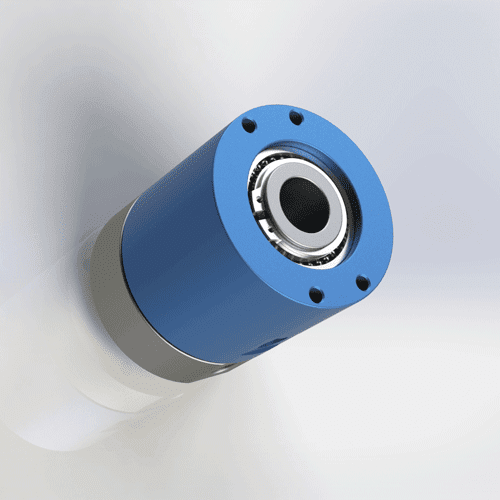

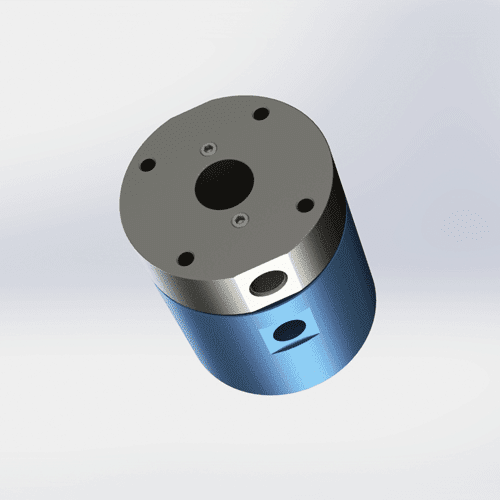

The rotary joint was identified as the missing link. Traditional fittings twisted hoses, disrupting air flow to the pneumatic cylinder. A custom 2-in 2-out rotary joint was selected, with one inlet for clamping air and the other for release, promising leak-free rotational movement up to 60 RPM.

Implementation: Seamless Integration for Flawless Workflow

Rollout at the supplier’s facility took five days, with zero line stoppage. Engineers mounted the rotary joint at the table’s central hub, connecting it to the fixture’s pneumatic cylinder via M8 threads. The first station activated the rotary joint‘s clamping inlet at 6 bar, securing the workpiece for hole drilling with 0.01mm accuracy. As the table rotated to the second station, the rotary joint maintained pressure, enabling threading without slippage.

The third station’s chamfering benefited from the rotary joint‘s dual-outlet design, channeling low-pressure air for edge finishing while preserving clamping force. By the fourth station, the pneumatic cylinder released on cue, allowing automated screw insertion and component assembly via robotic feeders. PLC integration synced the rotary joint with servo motors, ensuring synchronized rotational movement across all stations.

Calibration focused on the rotary joint‘s Teflon seals, tested under 20 MPa to confirm zero leaks during full cycles. The 4-station rotary indexing table now handled 1,200 parts per hour, up from 800.

Results: Quantifiable Gains in Precision and Productivity

The transformation was profound. Defect rates plunged 88% to under 3%, with the rotary joint‘s consistent clamping force eliminating 95% of slippage incidents. Throughput soared 50%, reaching 1,800 parts daily, while assembly times dropped 25% to 15 seconds per piece. Maintenance intervals extended from weekly to quarterly, saving $45K yearly in labor and parts. The pneumatic cylinder‘s reliability improved 40%, thanks to the rotary joint‘s uninterrupted air delivery.

“Replacing our fittings with the rotary joint was a no-brainer,” said Plant Manager Alex Rivera. “Our 4-station rotary indexing table now runs like clockwork, with rotary joint-driven clamping that’s spot-on every cycle.”

Why This Rotary Joint Elevates Your Machining Line

For manufacturers demanding rotational precision, the rotary joint offers scalability for multi-station setups and compliance with ISO 9001 standards. Its ability to sustain clamping force under rotational movement cuts energy waste by 15%, aligning with sustainable practices. In automotive and aerospace, where pneumatic cylinder reliability is paramount, this rotary joint is indispensable.

Ready to clamp down on inefficiencies? Explore how the rotary joint can revolutionize your 4-station rotary indexing table. Contact our team for tailored demos and seamless integration.