In industrial automation, a rotary joint is essential for fluid transfer in rotating machinery. Proper maintenance ensures your rotary joint lasts longer, reduces downtime, and avoids costly replacements. Whether it’s a pneumatic rotary joint for air or a hydraulic rotary joint for oil, regular care can extend its life by 50%. As a leading rotary joint manufacturer, Begapunk recommends a step-by-step approach based on real-world applications like laser cutting and CNC systems. Let’s break it down.

Step 1: Clean the Rotary Joint Regularly to Prevent Contamination

The first key to maintaining a rotary joint is keeping it clean. Dust, debris, or fluid buildup can cause leaks or wear. For a standard rotary joint, disconnect the supply lines and flush with a compatible cleaner—use mild detergent for air rotary joints or solvent for oil-based rotary joints. Avoid high-pressure washing, as it can damage seals.For example, in dusty environments like laser tube cutting, clean your rotary joint weekly. Use a soft brush to remove external dirt and inspect for cracks. This simple step can prevent 80% of common rotary joint failures, ensuring smooth rotation and fluid flow.

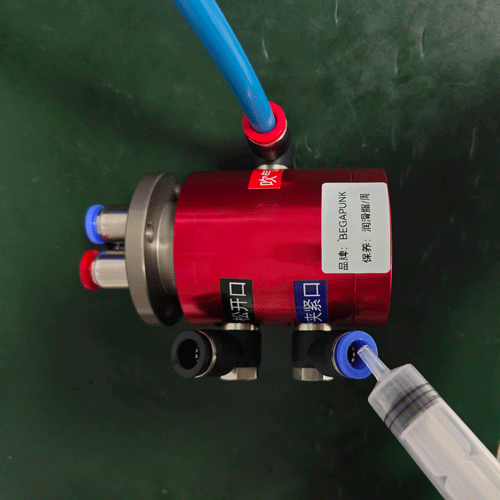

Step 2: Lubricate the Rotary Joint to Reduce Friction and Wear

Lubrication is crucial for any rotary joint‘s performance. High-speed rotary joints (over 500 RPM) need regular greasing to minimize friction. Apply a thin layer of lithium-based grease to the bearings and seals, following the manufacturer’s guidelines. For low-speed rotary joints, monthly lubrication suffices, but check for grease leakage during operation.At Begapunk, our rotary joint designs feature PTFE seals that require less lubrication, but we recommend using food-grade grease for clean environments. This maintenance practice can boost rotary joint efficiency by 25%, especially in high-temperature scenarios up to 150°C.

Step 3: Inspect Pressure, Temperature, and Environment for Early Issues

A thorough inspection is the final step in rotary joint maintenance. Check pressure ratings—ensure your rotary joint operates within 1-30MPa to avoid seal failure. Monitor temperature; for hot applications like steam rotary joints, use thermal imaging to spot hotspots.In dusty or corrosive settings, inspect for powder buildup or rust. Replace seals if pressure drops or leaks occur. For multi-channel rotary joints in laser cutting, test each channel separately. Regular checks every 3 months can identify 90% of potential problems, saving you from unexpected breakdowns.

Why Maintenance Matters for Your Rotary Joint

Maintaining a rotary joint isn’t just routine—it’s an investment. Poor upkeep leads to leaks, reduced speed, and downtime costs exceeding $10,000 per incident. With Begapunk’s rotary joints, built from stainless steel and PTFE, proper care extends lifespan to 500,000+ cycles. Whether you’re handling air, water, oil, or corrosive fluids, follow these steps for optimal performance.Ready to maintain your rotary joint or upgrade to a custom model? Contact us for expert advice and free maintenance tips.By Cao Guangcheng, Founder of Begapunk. With 10+ years in rotary joint engineering, we’ve helped OEMs worldwide optimize their systems.