Precision Engineering Unleashed: 2 Inlet and 2 Outlet Rotary Joint in 5-Axis Machining Center Fixtures

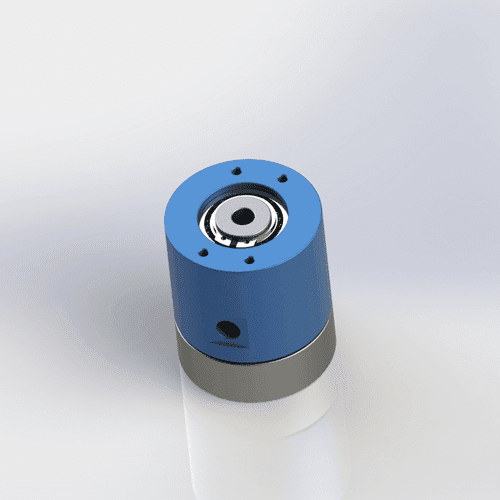

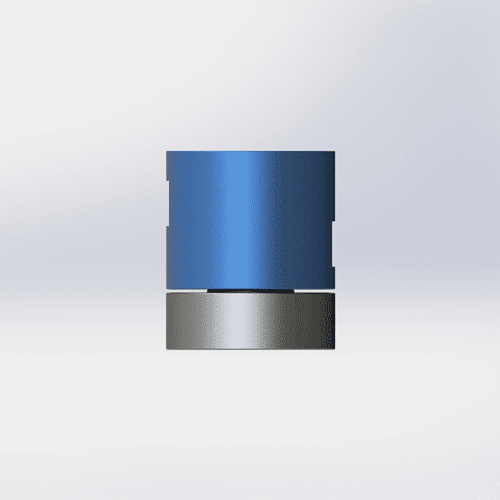

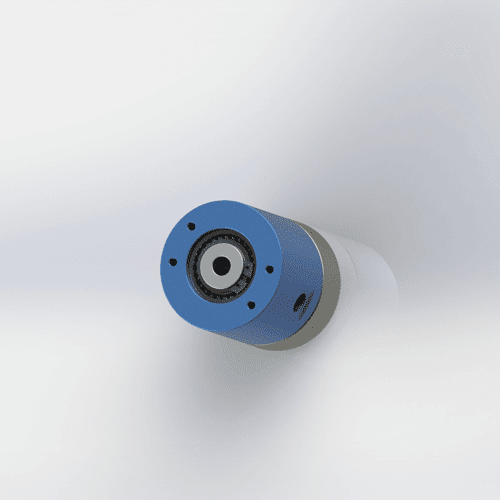

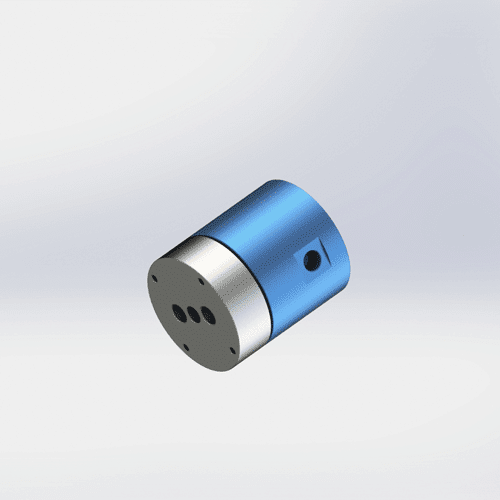

In the high-precision arena of advanced manufacturing, where tolerances are measured in microns, the 2 inlet and 2 outlet rotary joint redefines rotational dynamics for 5-axis machining centers. This compact rotary joint, featuring dual inlets for media supply and dual outlets for targeted delivery, integrates seamlessly into rotatable fixtures, enabling 360° uninterrupted operation without hose entanglement. Ideal for complex milling, drilling, and contouring tasks, the M8 threading ensures robust compatibility, while its lightweight aluminum construction minimizes inertia in dynamic setups. For U.S. and European fabricators pushing the boundaries of aerospace and automotive parts, this M8 rotary joint empowers 5-axis machining with flawless fluid and pneumatic control, slashing cycle times and elevating part quality.

Why the 2 Inlet and 2 Outlet Rotary Joint Excels in Rotatable Fixtures

Engineered for endurance, the 2 inlet and 2 outlet M8 rotary joint supports pressures up to 25 MPa and speeds to 2000 RPM, with Teflon seals that resist wear in oily environments. One inlet-outlet pair handles coolant for chip evacuation, while the second manages pneumatic clamping—critical for secure workpiece rotation in 5-axis machining centers. The M8 ports facilitate quick swaps, reducing setup from hours to minutes, and its IP65 rating shields against coolant splatter. Traditional swivels falter under multi-axis stress, but this rotary joint delivers zero leaks, enhancing rotatable fixture stability for intricate geometries like turbine blades.

Case Study: Revolutionizing Aerospace Components at AeroForge Ltd.

AeroForge Ltd., a UK-based specialist in titanium aerospace forgings, encountered bottlenecks in their 5-axis machining center line. Rotatable fixtures tangled coolant lines during 360° indexing, causing thermal inconsistencies and 22% defect rates in blade profiles—incurring €120K in scrap and rework annually.

The retrofit with the 2 inlet and 2 outlet M8 rotary joint proved transformative. Mounted at the fixture’s swivel hub, two units per station routed coolant through the first pair for flood machining and air blasts via the second for debris clearance, syncing with CAD/CAM paths for seamless rotational movement. Integrated into 12 Haas VF-5 machines, it handled 50mm bores for high-flow demands.

Results shone brightly:

Cycle Time Reduction: Machining sped up 45%, from 15 to 8 minutes per blade, hitting 800 parts weekly.

Quality Surge: Surface finishes improved to Ra 0.8μm, with defect rates dropping to 2% thanks to consistent rotary joint flow.

Maintenance Savings: Downtime halved, as the M8 seals endured 15,000 cycles without failure—ROI in 10 weeks.

Scalability Win: Easy M8 threading allowed expansion to multi-fixture pods, boosting throughput 30%.

“The 2 inlet and 2 outlet M8 rotary joint turned our 5-axis machining center into a precision symphony,” enthused Production Manager Elena Ruiz. “Our rotatable fixtures now rotate with surgical accuracy, no strings attached.”

Maximize Your 5-Axis Potential with This Rotary Joint

For innovators in precision machining, the 2 inlet and 2 outlet M8 rotary joint offers versatility across media types and compliance with ISO 9001 standards. It cuts energy use by optimizing flow in rotatable fixtures, aligning with sustainable practices. In a market demanding faster iterations, this M8 rotary joint is the key to unlocking superior 5-axis machining performance.

Upgrade your setup now—discover how the 2 inlet and 2 outlet M8 rotary joint can supercharge your 5-axis machining center. Connect with our experts for tailored demos and installations.