Streamlining Robotic Precision: Integrated Electrical Slip Ring for Multi-Solenoid Valve Rotational Movement

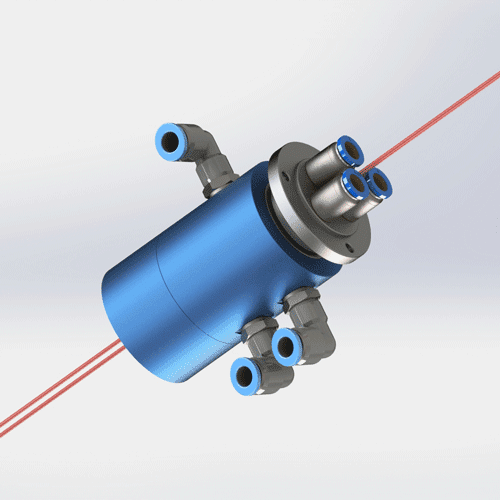

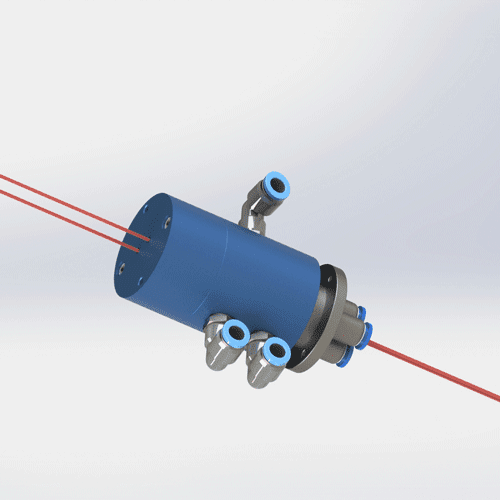

In the dynamic landscape of industrial automation, where agility meets accuracy, the integrated electrical slip ring revolutionizes rotational movement in robotic end effectors. This compact powerhouse seamlessly transmits power and signals to multiple solenoid valves at the arm’s tip, enabling 360° uninterrupted operation without cable tangling. Designed for high-reliability environments, the electrical slip ring supports up to 24 circuits for precise valve actuation, making it essential for assembly lines, material handling, and quality inspection systems. For North American and European manufacturers seeking to enhance robotic efficiency, this integrated slip ring delivers flawless rotational movement for solenoid valves, minimizing downtime and boosting throughput.

The Core Advantages of the Integrated Electrical Slip Ring

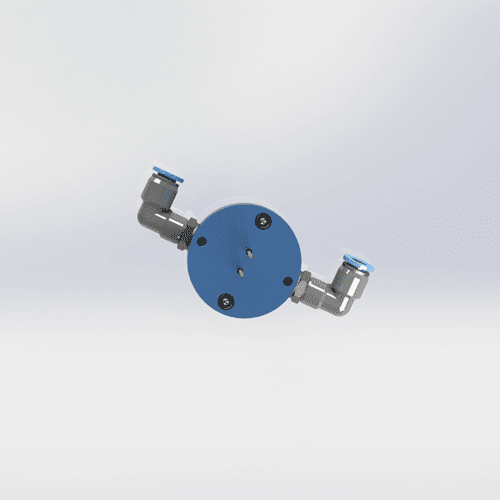

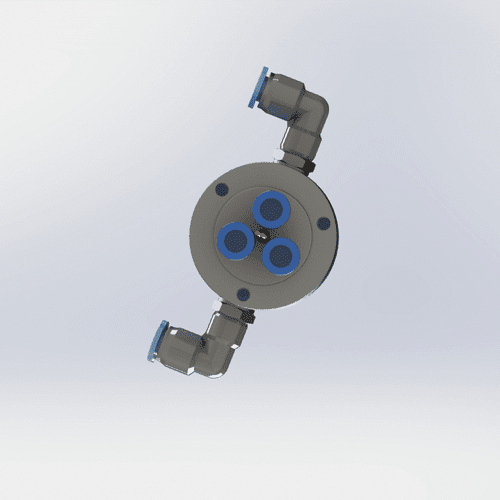

At its heart, the integrated electrical slip ring combines conductive rings and brushes in a low-friction, maintenance-free housing, rated for speeds up to 1000 RPM and currents to 10A per channel. Gold-gold contacts ensure low noise and high signal integrity, ideal for controlling solenoid valves in pneumatic or hydraulic setups. Unlike traditional pigtail cables that fail under constant rotational movement, this slip ring integrates Ethernet, USB, and power lines into one unit, reducing weight by 30% on end effectors. Its IP65 sealing protects against dust and moisture, supporting continuous solenoid valve switching in harsh factory floors.

Case Study: Elevating Assembly at Precision Robotics Inc.

Precision Robotics Inc., a Detroit-based leader in automotive automation, struggled with cable wear in their welding robots. Equipped with six solenoid valves for gripper and torch positioning, the end effectors jammed during 360° rotational movement, causing 18% production halts and $75K in quarterly repairs.

The adoption of the integrated electrical slip ring turned the tide. Retrofitted into the robot’s wrist joint, the unit powered and signaled all solenoid valves via 12 dedicated circuits—one inlet for control signals, one outlet for feedback—enabling fluid rotational movement across weld seams. Deployed on 20 arms in a single line, it synced with PLC systems for millisecond valve responses.

The impact was profound:

Uptime Leap: Downtime fell 75%, with the slip ring enduring 50,000 cycles without signal loss.

Precision Boost: Solenoid valve actuation accuracy reached 99.7%, eliminating weld defects in rotational movement phases.

Efficiency Gains: Cycle times shaved 25% to 45 seconds per part, ramping output to 1,200 assemblies daily.

Cost Recovery: ROI achieved in eight weeks, as the integrated electrical slip ring cut cabling costs by 40%.

“This electrical slip ring unlocked true freedom in our rotational movement—our solenoid valves now dance without a hitch,” noted Engineering Lead Maria Voss. “It’s the backbone of our smart factory evolution.”

Why Integrate This Slip Ring into Your Automation?

For forward-thinking engineers, the integrated electrical slip ring offers scalability for multi-valve configurations and compatibility with Industry 4.0 protocols. It enhances safety by eliminating loose wires during rotational movement and supports eco-friendly ops with energy-efficient designs. In a competitive market, this slip ring empowers solenoid valves to perform at peak, driving innovation in robotics.

Transform your end effectors today—explore the integrated electrical slip ring for superior rotational movement. Contact our specialists for custom demos and integrations tailored to your line.