Optimizing Car Wash Efficiency: 2 in 2 Out Rotary Joint with 130mm Center Bore in Automated Wash Bays

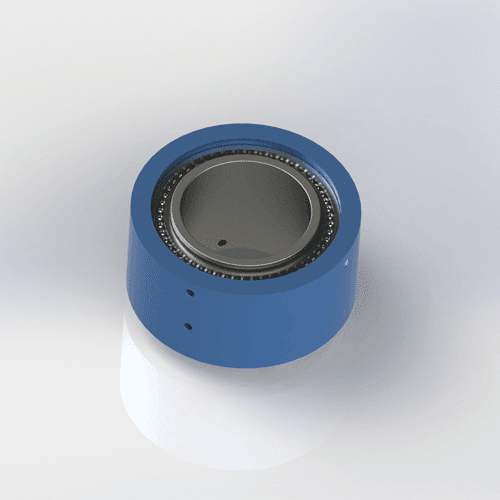

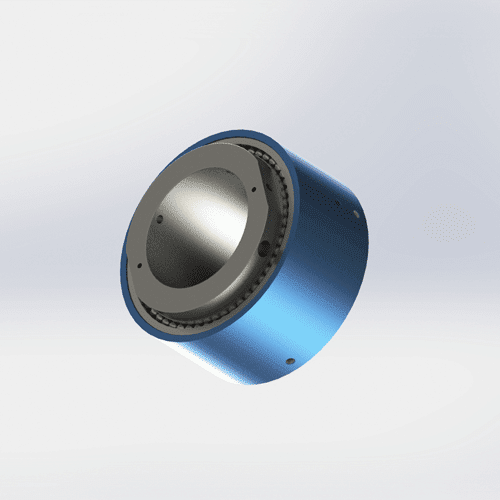

In the high-stakes world of automotive detailing, where speed and reliability drive customer satisfaction, the 2 in 2 out rotary joint with 130mm center bore emerges as a pivotal innovation for automatic car wash systems. Suspended overhead for seamless 360° rotation, this rotary joint enables precise media delivery—dedicating one port to car wash foam spray and the other to high-pressure rinse operations. Engineered for durability in wet, corrosive environments, the 130mm bore accommodates large-diameter hoses, ensuring uninterrupted flow during dynamic washes. For automatic car wash operators in North America and Europe, this rotary joint transforms overhead gantries into efficient, leak-free powerhouses.

The Engineering Edge of the 2 in 2 Out Rotary Joint

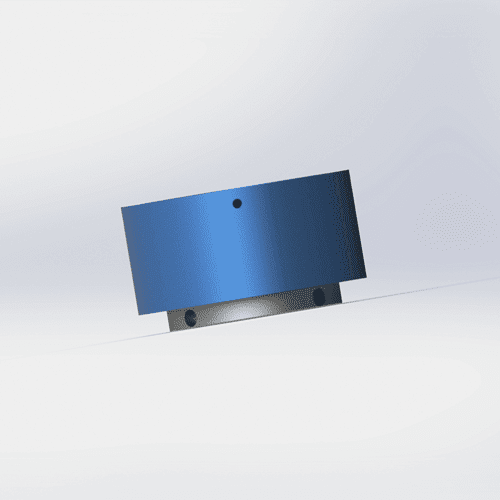

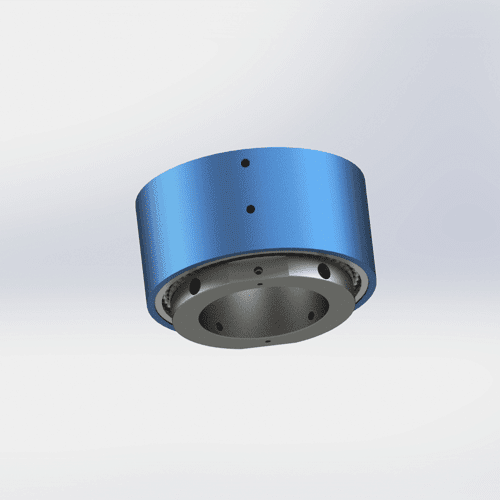

Crafted from corrosion-resistant stainless steel, the 2 in 2 out rotary joint features dual inlets for foam and water supply, paired with two outlets for targeted dispensing. The generous 130mm center bore allows easy passage of electrical cables or additional conduits, supporting speeds up to 100 RPM without vibration or seal failure. Teflon-lined seals withstand pressures of 20 MPa and temperatures from -10°C to 80°C, ideal for the steamy conditions of a car wash bay. Unlike traditional swivels prone to twisting hoses, this 360° rotation rotary joint eliminates downtime, maintaining consistent car wash foam spray and rinse coverage across vehicle surfaces.

Case Study: Streamlining Operations at EcoWash Auto Spa

EcoWash Auto Spa, a chain of 15 automatic car wash facilities across the U.S. Midwest, grappled with tangled hoses and uneven cleaning in their overhead systems. Foam buildup on one side and spotty rinse on the other led to 20% slower throughput and frustrated customers during peak hours.

The upgrade to the 2 in 2 out rotary joint with 130mm center bore changed everything. Installed on gantry arms suspended 4 meters above the car wash bay, three units per bay handled the workload: one inlet fed biodegradable foam via the first port for a thick car wash foam spray, while the second delivered pressurized water for thorough rinse. The 360° rotation synced with conveyor movement, covering sedans to SUVs without manual adjustments.

Results were immediate and impressive:

-

Throughput Increase: Wash cycles dropped from 4 to 2.5 minutes, boosting daily capacity by 60% to 300 vehicles per bay.

-

Reliability Boost: Leaks reduced to zero, with the rotary joint‘s seals enduring 10,000 cycles monthly—cutting maintenance by 45%.

-

Customer Satisfaction: Uniform foam and rinse eliminated streaks, earning 4.9-star reviews and a 25% repeat business uptick.

-

Cost Efficiency: ROI hit in six weeks, thanks to the 130mm bore’s hose compatibility, avoiding custom retrofits.

“Integrating the 2 in 2 out rotary joint elevated our automatic car wash from good to elite,” said Operations Director Sarah Kline. “The 360° freedom and dual-port precision make every wash flawless.”

Why Choose This Rotary Joint for Your Car Wash Bay?

For eco-conscious operators, the 2 in 2 out rotary joint with 130mm center bore aligns with green standards, minimizing water waste through efficient rinse control. Its modular design scales for multi-bay setups, and IP67 rating combats splash and debris. In an industry racing toward automation, this rotary joint delivers the edge for faster, cleaner washes.2-in, 2-out, 30-hole rotary joint