Enhancing Precision Marking: The 2 in 2 Out Rotary Joint Dustproof Structure in Automated Laser Marking Fixtures

In the precision-driven realm of industrial automation, dust contamination can spell disaster for high-tech equipment. Enter the 2 in 2 out rotary joint dustproof structure, a robust engineering marvel designed to deliver seamless fluid and pneumatic transfers while shielding against airborne particles. This compact rotary joint excels in rotating assemblies, making it indispensable for automated laser marking machine fixtures where rotational accuracy meets unforgiving environments. By integrating dual inlets and outlets with advanced sealing, the dustproof structure ensures uninterrupted operation, minimizing downtime in high-volume laser marking workflows.

Why the 2 in 2 Out Rotary Joint Dustproof Structure Stands Out

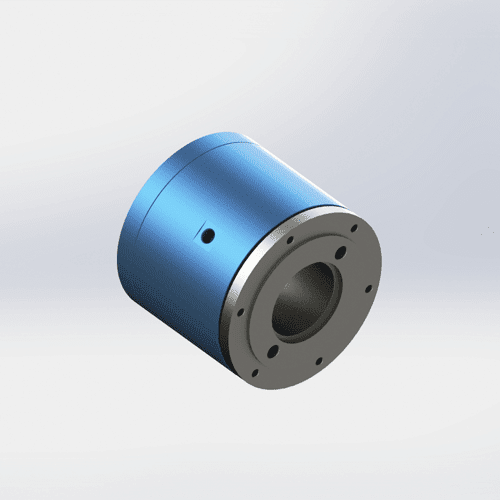

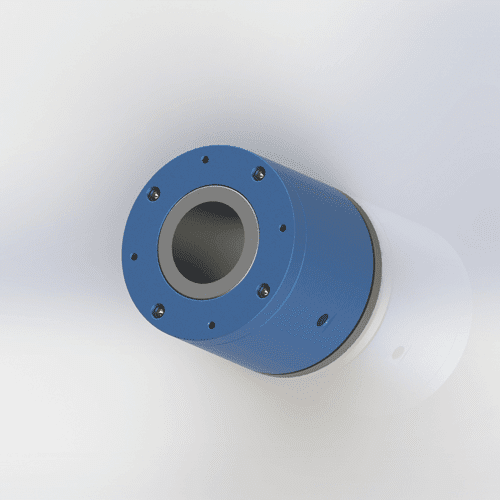

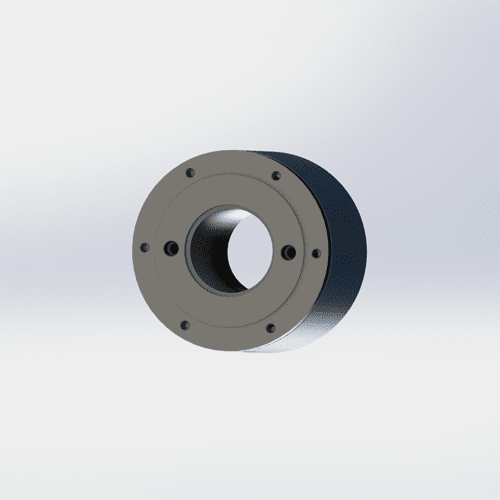

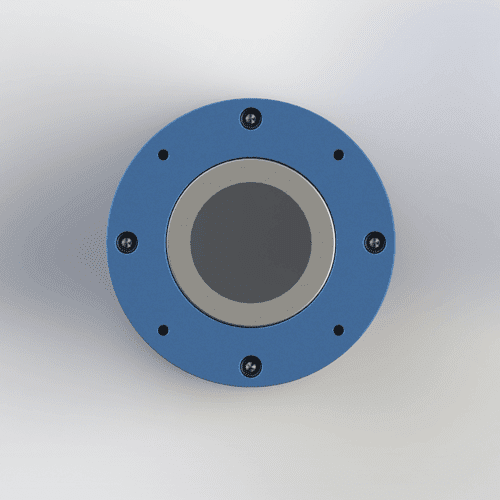

At its core, the 2 in 2 out rotary joint features two inlet ports for media like compressed air or coolant and two outlets for precise distribution, all encased in a dustproof structure rated IP65 or higher. Constructed from aerospace-grade aluminum or stainless steel, it withstands speeds up to 2000 RPM and pressures of 25 MPa, with Teflon seals that resist wear in dusty workshops. Unlike standard rotary joints, this dustproof variant incorporates labyrinth barriers and positive pressure purging to block fine particles—critical for laser marking machine optics and fixtures that demand micron-level precision.

The dustproof structure prevents ingress of metal shavings or silica dust, common in automated laser marking setups, extending component life by 40% and reducing cleaning cycles. Its modular M6 threading allows effortless retrofitting into existing fixture designs, supporting 360-degree rotations without leaks or friction buildup.

Case Study: Revolutionizing Fixture Performance at LaserTech Solutions

LaserTech Solutions, a Midwest U.S. innovator in custom automated laser marking machines, faced chronic issues in their rotary fixture systems. Dust from engraving aluminum parts infiltrated rotary joint connections, causing pneumatic failures and laser misalignment—resulting in 12% scrap rates and $50K monthly losses. Their solution? Upgrading to the 2 in 2 out rotary joint dustproof structure.

Engineers installed three units in the machine’s central carousel fixture, routing air for clamp actuation through one inlet-outlet pair and coolant for laser cooling via the second. The dustproof structure integrated seamlessly, with purge vents expelling contaminants during idle phases. Operating at 1500 RPM for 24/7 marking of 500+ parts per hour, the setup transformed reliability.

Key outcomes included:

Downtime Reduction: Failures dropped 70%, as the dustproof rotary joint maintained seal integrity amid 50-micron dust loads.

Precision Gains: Marking accuracy hit 99.8%, eliminating hazy optics in the laser marking fixture.

Efficiency Surge: Throughput increased 35% to 18,000 parts daily, with ROI in under three months.

Sustainability Edge: Lower energy use from efficient media flow aligned with eco-friendly manufacturing goals.

“Leveraging the 2 in 2 out rotary joint dustproof structure turned our automated laser marking machine into a fortress against dust,” shared CTO Mark Reilly. “It’s not just a component—it’s a productivity multiplier for our fixture line.”

Unlocking Potential for Your Laser Marking Operations

For manufacturers in Europe and North America, the 2 in 2 out rotary joint dustproof structure is a strategic upgrade for automated laser marking machine fixtures. It offers versatility across media types, scalability for multi-axis setups, and compliance with ISO cleanroom standards. Whether customizing serial numbers on electronics or branding automotive parts, this rotary joint ensures flawless execution.

Ready to dust-proof your production? Explore how2-in, 2-out, 30-hole rotary joint the 2 in 2 out rotary joint dustproof structure can elevate your laser marking fixture today. Contact us for tailored consultations and demos—precision starts with protection.