In industrial automation, a rotary joint is vital for fluid transfer in rotating machinery. But when a rotary joint malfunctions, it can halt production and rack up costs. As a specialized rotary joint manufacturer, Begapunk has helped countless OEMs diagnose problems swiftly. This guide focuses on troubleshooting a rotary joint by checking seals and bearings—the two most common culprits. Whether your rotary joint is leaking air or vibrating excessively, follow these steps to identify and resolve issues. Proper troubleshooting can extend rotary joint life by 50% and reduce downtime.

Step 1: Addressing Leaks in Your Rotary Joint

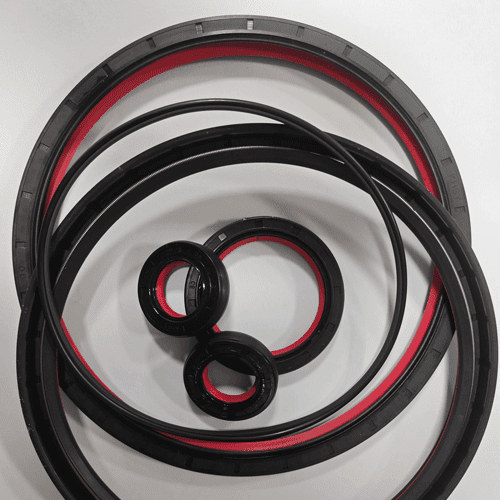

Leaks are the most frequent rotary joint problem, often stemming from seal wear. Always start by inspecting the seals for damage like cracks or deformation.

- Rotary Joint Leaking Oil: If your rotary joint leaks oil, check the seals for damage. Worn PTFE seals in hydraulic rotary joints are common in high-pressure CNC systems.

- Rotary Joint Leaking Water: For rotary joint leaking water, inspect the seals for damage. This issue frequently occurs in cooling lines, where corrosion accelerates seal failure.

- Rotary Joint Leaking Air: A rotary joint leaking air requires examining the seals for damage, especially in pneumatic rotary joints for laser cutting, where air pressure drops signal wear.

- Rotary Joint Leaking Gas: If the rotary joint leaks gas, check the seals for damage. Gas rotary joints in robotics demand tight seals to prevent safety hazards.

- Rotary Joint Leaking Powder: For rotary joint leaking powder, inspect the seals for damage. Powder-handling rotary joints in mills need dust-resistant seals to avoid clogs.

- Rotary Joint Leaking Steam: A rotary joint leaking steam calls for checking the seals for damage, as high-temperature steam in paper mills erodes standard seals quickly.

- Rotary Joint Leaking Chemicals: If your rotary joint leaks chemicals, examine the seals for damage. Chemical rotary joints require Viton seals to resist corrosion.

- Rotary Joint Leaking Hydraulic Oil: For rotary joint leaking hydraulic oil, check the seals for damage. Hydraulic rotary joints in heavy machinery often fail under pressure spikes.

- Rotary Joint Leaking Coolant: A rotary joint leaking coolant needs seal inspection for damage, common in CNC setups where coolant maintains tool temperatures.

- Rotary Joint Leaking Cutting Fluid: If the rotary joint leaks cutting fluid, check the seals for damage. Cutting fluid rotary joints in machining demand robust seals against abrasives.

- Rotary Joint Leaking Vacuum: For rotary joint leaking vacuum, inspect the seals for damage. Vacuum rotary joints in packaging lines rely on airtight seals.

- Rotary Joint Leaking High Pressure: A rotary joint leaking high pressure requires checking the seals for damage, as pressures over 30MPa test seal integrity.

- Rotary Joint Leaking Low Pressure: If the rotary joint leaks low pressure, examine the seals for damage, even subtle wear causes issues in precision applications.

- Rotary Joint Leaking High Temperature: For rotary joint leaking high temperature, check the seals for damage. High-temp rotary joints in steam systems need heat-resistant materials.

- Rotary Joint Leaking Low Temperature: A rotary joint leaking low temperature calls for seal inspection for damage, as cold can harden seals.

If seals are damaged, replace them with OEM parts like Begapunk’s PTFE seals for rotary joints, designed to withstand diverse conditions.

Step 2: Troubleshooting Movement and Performance Issues in Rotary Joints

If your rotary joint isn’t rotating properly, the bearings are often to blame. Bearings handle friction, and damage leads to operational failures.

- Rotary Joint Not Rotating: If the rotary joint doesn’t rotate, check the bearings for damage. Seized bearings in low-speed rotary joints signal lubrication failure.

- Rotary Joint Overheating: For rotary joint overheating, inspect the bearings for damage. Friction in high-speed rotary joints generates heat, risking seal meltdown.

- Rotary Joint Making Noise: A rotary joint making noise requires examining the bearings for damage. Noisy rotary joints in CNC lines indicate worn ball bearings.

- Rotary Joint Vibrating: If the rotary joint vibrates, check the bearings for damage. Vibration in multi-channel rotary joints can stem from unbalanced loads.

- Rotary Joint Leaking at High Speed: For rotary joint leaking at high speed, inspect the bearings for damage. High RPM stresses bearings in laser cutting rotary joints.

- Rotary Joint Leaking at Low Speed: A rotary joint leaking at low speed calls for bearing checks for damage, as even slow rotation wears seals if bearings fail.

Replace damaged bearings promptly—Begapunk’s rotary joints use high-grade ball bearings for 500,000+ cycles.

Final Tips for Rotary Joint Troubleshooting Success

Troubleshooting a rotary joint starts with seals for leaks and bearings for performance issues. Regular inspections every 3 months prevent 80% of failures. If problems persist, consult a rotary joint specialist. At Begapunk, our rotary joints are built for durability, but we offer free troubleshooting support for our 20K+ annual OEM units.Facing rotary joint issues? Contact us for expert diagnostics and replacements.By the Begapunk Team. With expertise in rotary joint engineering, we’ve resolved thousands of troubleshooting cases worldwide.