The Basic Function of a Rotary Joint

Types of Rotary Joints: Finding the Right Fit

Not all rotary joints are created equal. Understanding the types helps select the ideal one for your needs. Here’s a breakdown:

- Pneumatic Rotary Joints: Designed for compressed air transfer, these rotary joints excel in automation lines. With multi-channel configurations, they handle clamping and unclamping in laser cutting machines, operating at pressures from 1-10 bar. Begabunk’s pneumatic rotary joints feature PTFE seals for low friction and long life.

- Hydraulic Rotary Joints: For high-pressure fluids, hydraulic rotary joints support up to 30MPa, ideal for heavy machinery like CNC lathes. Our stainless steel rotary joints in this category include anodized surfaces for corrosion resistance in harsh environments.

- Single vs. Multi-Channel Rotary Joints: Single-channel rotary joints suit basic applications, while multi-channel versions—like our 4-inlet 4-outlet rotary joint—manage multiple fluids simultaneously. This versatility reduces the need for multiple connections, cutting installation time by 25%.

- High-Speed Rotary Joints: Engineered for speeds over 500 RPM, these rotary joints use advanced bearings to prevent vibration. In paper mills or packaging, a high-speed rotary joint ensures uninterrupted flow, boosting throughput.

Choosing the right rotary joint depends on your media type, pressure, and rotation speed. At Begapunk, we customize rotary joints to match your specs, ensuring optimal performance.

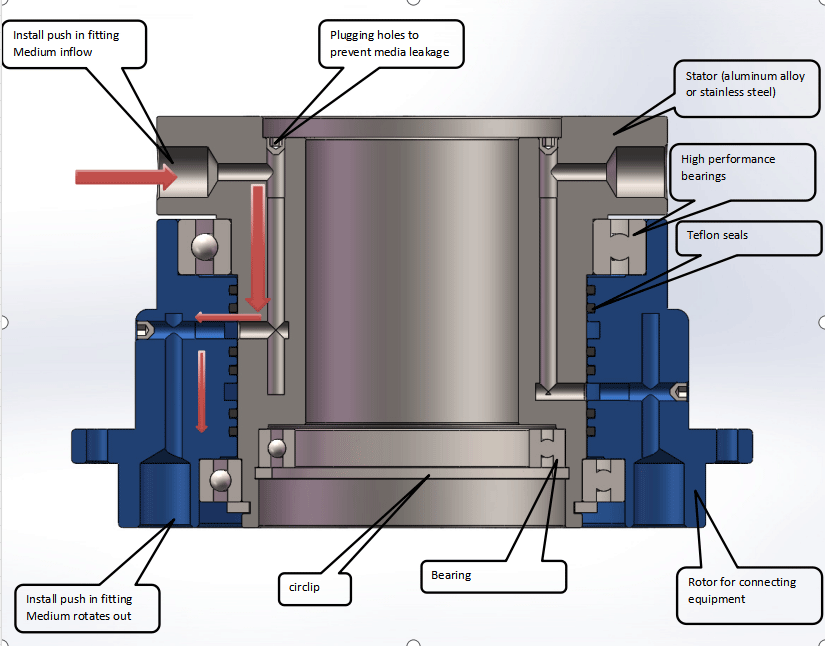

Key Components of a Rotary Joint

To appreciate a rotary joint‘s reliability, let’s look under the hood. The core elements include:

- Housing and Shaft: The stationary housing connects to the supply, while the rotating shaft aligns with the machine. Materials like aluminum alloy or stainless steel ensure durability, with Begapunk’s rotary joints offering anodized finishes for corrosion protection.

- Seals and Bearings: PTFE or carbon seals prevent leaks, while ball bearings minimize wear. In our rotary joints, these components support temperatures from -20°C to 100°C, ideal for diverse industrial uses.

- Ports and Channels: Inlet and outlet ports allow fluid entry/exit. Multi-channel rotary joints like our 3-in-3-out model feature dedicated paths for air, water, and oil, enabling complex operations without cross-contamination.

These components make a rotary joint robust, with our models tested for 500,000+ cycles. A quality rotary joint isn’t just a part—it’s a system safeguard.

Applications of Rotary Joints in Industry

Rotary joints power a wide range of industries, from manufacturing to energy. Here’s where they shine:

- Laser Tube Cutting: In CNC laser machines, a rotary joint rotates tubes while delivering air for clamping and dust removal. Begapunk’s rotary joints reduce slippage, improving cut accuracy by 15%.

- Paper and Textile Mills: For drying cylinders or winding machines, rotary joints transfer steam or water at high speeds. Our rotary joints handle 600 RPM, minimizing steam leaks and energy waste.

- Packaging and Robotics: In automated lines, rotary joints support pneumatic tools for precise gripping. With PTFE seals, they ensure zero downtime in 24/7 operations.

- Heavy Machinery: Hydraulic rotary joints in excavators or cranes manage oil flow under 30MPa. Begabunk’s designs feature multi-channel setups for enhanced safety.

Across these applications, a reliable rotary joint cuts maintenance costs by 35%, as seen in our 20K+ annual units supplied to OEMs